1. Innføring

Configuration moves from theory to device — HAL device that is. For those who have had just a bit of computer programming, this section is the Hello World of the HAL.

halrun can be used to create a working system. It is a command line or text file tool for configuration and tuning. The following examples illustrate its setup and operation.

2. Halcmd

halcmd is a command line tool for manipulating HAL. A more complete man page exists for halcmd and installed together with LinuxCNC, from source or from a package. If LinuxCNC has been compiled as run-in-place, the man page is not installed but is accessible in the LinuxCNC main directory with the following command:

$ man -M docs/man halcmd2.1. Notation

For this tutorial, commands for the operating system are typically shown without the prompt provided by the UNIX shell, i.e typically a dollar sign ($) or a hash/double cross (#). When communicating directly with the HAL through halcmd or halrun, the prompts are shown in the examples. The terminal window is in Applications/Accessories from the main Ubuntu menu bar.

me@computer:~linuxcnc$ halrun

(vil vises som påfølgende linje)

halrun

(the halcmd: prompt will be shown when running HAL)

halcmd: loadrt counter

halcmd: show pin2.2. Tab-completion

Your version of halcmd may include tab-completion. Instead of completing file names as a shell does, it completes commands with HAL identifiers. You will have to type enough letters for a unique match. Try pressing tab after starting a HAL command:

halcmd: loa<TAB>

halcmd: load

halcmd: loadrt

halcmd: loadrt cou<TAB>

halcmd: loadrt counter2.3. The RTAPI environment

RTAPI stands for Real Time Application Programming Interface. Many HAL components work in realtime, and all HAL components store data in shared memory so realtime components can access it. Regular Linux does not support realtime programming or the type of shared memory that HAL needs. Fortunately, there are realtime operating systems (RTOS’s) that provide the necessary extensions to Linux. Unfortunately, each RTOS does things a little differently.

To address these differences, the LinuxCNC team came up with RTAPI, which provides a consistent way for programs to talk to the RTOS. If you are a programmer who wants to work on the internals of LinuxCNC, you may want to study linuxcnc/src/rtapi/rtapi.h to understand the API. But if you are a normal person, all you need to know about RTAPI is that it (and the RTOS) needs to be loaded into the memory of your computer before you do anything with HAL.

3. A Simple Example

3.1. Loading a component

For this tutorial, we are going to assume that you have successfully installed the Live CD and, if using a RIP

[Run In Place, when the source files have been downloaded to a user directory and are compiled and executed directly from there.]

, invoke the rip-environment script to prepare your shell. In that case, all you need to do is load the required RTOS and RTAPI modules into memory. Just run the following command from a terminal window:

cd linuxcnc

halrun

halcmd:With the realtime OS and RTAPI loaded, we can move into the first example. Notice that the prompt is now shown as halcmd:. This is because subsequent commands will be interpreted as HAL commands, not shell commands.

For the first example, we will use a HAL component called siggen, which is a simple signal generator. A complete description of the siggen component can be found in the SigGen section of this Manual. It is a realtime component. To load the "siggen" component, use the HAL command loadrt.

halcmd: loadrt siggen3.2. Examining the HAL

Now that the module is loaded, it is time to introduce halcmd, the command line tool used to configure the HAL. This tutorial will introduce only a selection of halcmd features. For a more complete description try man halcmd, or see the reference in HAL Commands section of this document. The first halcmd feature is the show command. This command displays information about the current state of the HAL. To show all installed components:

halrun/halcmdhalcmd: show comp

Loaded HAL Components:

ID Type Name PID State

3 RT siggen ready

2 User halcmd2177 2177 readySince halcmd itself is also a HAL component, it will always show up in the list. The number after "halcmd" in the component list is the UNIX process ID. It is possible to run more than one copy of halcmd at the same time (in different terminal windows for example), so the PID is added to the end of the name to make it unique. The list also shows the siggen component that we installed in the previous step. The RT under Type indicates that siggen is a realtime component. The User under Type indicates it is a non-realtime component.

Next, let’s see what pins siggen makes available:

halcmd: show pin

Component Pins:

Owner Type Dir Value Name

3 float IN 1 siggen.0.amplitude

3 bit OUT FALSE siggen.0.clock

3 float OUT 0 siggen.0.cosine

3 float IN 1 siggen.0.frequency

3 float IN 0 siggen.0.offset

3 float OUT 0 siggen.0.sawtooth

3 float OUT 0 siggen.0.sine

3 float OUT 0 siggen.0.square

3 float OUT 0 siggen.0.triangleThis command displays all of the pins in the current HAL. A complex system could have dozens or hundreds of pins. But right now there are only nine pins. Of these pins eight are floating point and one is bit (boolean). Six carry data out of the siggen component and three are used to transfer settings into the component. Since we have not yet executed the code contained within the component, some the pins have a value of zero.

The next step is to look at parameters:

halcmd: show param

Parameters:

Owner Type Dir Value Name

3 s32 RO 0 siggen.0.update.time

3 s32 RW 0 siggen.0.update.tmaxThe show param command shows all the parameters in the HAL. Right now, each parameter has the default value it was given when the component was loaded. Note the column labeled Dir. The parameters labeled -W are writable ones that are never changed by the component itself, instead they are meant to be changed by the user to control the component. We will see how to do this later. Parameters labeled R- are read only parameters. They can be changed only by the component. Finally, parameter labeled RW are read-write parameters. That means that they are changed by the component, but can also be changed by the user. Note: The parameters siggen.0.update.time and siggen.0.update.tmax are for debugging purposes and won’t be covered in this section.

Most realtime components export one or more functions to actually run the realtime code they contain. Let’s see what function(s) siggen exported:

halcmd`halcmd: show funct

Exported Functions:

Owner CodeAddr Arg FP Users Name

00003 f801b000 fae820b8 YES 0 siggen.0.updateThe siggen component exported a single function. It requires floating point. It is not currently linked to any threads, so users is zero

[CodeAddr and Arg fields were used during development and should probably disappear.]

.

3.3. Making realtime code run

To actually run the code contained in the function siggen.0.update, we need a realtime thread. The component called threads that is used to create a new thread. Lets create a thread called "test-thread" with a period of 1 ms (1,000 µs or 1,000,000 ns):

halcmd: loadrt threads name1=test-thread period1=1000000Let’s see if that worked:

halcmd: show thread

Realtime Threads:

Period FP Name ( Time, Max-Time )

999855 YES test-thread ( 0, 0 )It did. The period is not exactly 1,000,000 ns because of hardware limitations, but we have a thread that runs at approximately the correct rate, and which can handle floating point functions. The next step is to connect the function to the thread:

halcmd: addf siggen.0.update test-threadUp till now, we’ve been using halcmd only to look at the HAL. However, this time we used the addf (add function) command to actually change something in the HAL. We told halcmd to add the function siggen.0.update to the thread test-thread, and if we look at the thread list again, we see that it succeeded:

halcmd: show thread

Realtime Threads:

Period FP Name ( Time, Max-Time )

999855 YES test-thread ( 0, 0 )

1 siggen.0.updateThere is one more step needed before the siggen component starts generating signals. When the HAL is first started, the thread(s) are not actually running. This is to allow you to completely configure the system before the realtime code starts. Once you are happy with the configuration, you can start the realtime code like this:

halcmd: startNow the signal generator is running. Let’s look at its output pins:

halcmd: show pin

Component Pins:

Owner Type Dir Value Name

3 float IN 1 siggen.0.amplitude

3 bit OUT FALSE siggen.0.clock

3 float OUT -0.1640929 siggen.0.cosine

3 float IN 1 siggen.0.frequency

3 float IN 0 siggen.0.offset

3 float OUT -0.4475303 siggen.0.sawtooth

3 float OUT 0.9864449 siggen.0.sine

3 float OUT -1 siggen.0.square

3 float OUT -0.1049393 siggen.0.triangleAnd let’s look again:

halcmd: show pin

Component Pins:

Owner Type Dir Value Name

3 float IN 1 siggen.0.amplitude

3 bit OUT FALSE siggen.0.clock

3 float OUT 0.0507619 siggen.0.cosine

3 float IN 1 siggen.0.frequency

3 float IN 0 siggen.0.offset

3 float OUT -0.516165 siggen.0.sawtooth

3 float OUT 0.9987108 siggen.0.sine

3 float OUT -1 siggen.0.square

3 float OUT 0.03232994 siggen.0.triangleWe did two show pin commands in quick succession, and you can see that the outputs are no longer zero. The sine, cosine, sawtooth, and triangle outputs are changing constantly. The square output is also working, however it simply switches from +1.0 to -1.0 every cycle.

3.4. Changing Parameters

The real power of HAL is that you can change things. For example, we can use the setp command to set the value of a parameter. Let’s change the amplitude of the signal generator from 1.0 to 5.0:

halcmd: setp siggen.0.amplitude 5halcmd: show param

Parameters:

Owner Type Dir Value Name

3 s32 RO 1754 siggen.0.update.time

3 s32 RW 16997 siggen.0.update.tmax

halcmd: show pin

Component Pins:

Owner Type Dir Value Name

3 float IN 5 siggen.0.amplitude

3 bit OUT FALSE siggen.0.clock

3 float OUT 0.8515425 siggen.0.cosine

3 float IN 1 siggen.0.frequency

3 float IN 0 siggen.0.offset

3 float OUT 2.772382 siggen.0.sawtooth

3 float OUT -4.926954 siggen.0.sine

3 float OUT 5 siggen.0.square

3 float OUT 0.544764 siggen.0.triangleNote that the value of parameter siggen.0.amplitude has changed to 5, and that the pins now have larger values.

3.5. Saving the HAL configuration

Most of what we have done with halcmd so far has simply been viewing things with the show command. However two of the commands actually changed things. As we design more complex systems with HAL, we will use many commands to configure things just the way we want them. HAL has the memory of an elephant, and will retain that configuration until we shut it down. But what about next time? We don’t want to manually enter a bunch of commands every time we want to use the system.

halcmd: save

# components

loadrt threads name1=test-thread period1=1000000

loadrt siggen

# pin aliases

# signals

# nets

# parameter values

setp siggen.0.update.tmax 14687

# realtime thread/function links

addf siggen.0.update test-threadThe output of the save command is a sequence of HAL commands. If you start with an empty HAL and run all these commands, you will get the configuration that existed when the save command was issued. To save these commands for later use, we simply redirect the output to a file:

halcmdhalcmd: save all saved.hal3.6. Exiting halrun

When you’re finished with your HAL session type exit at the "halcmd:" prompt. This will return you to the system prompt and close down the HAL session. Do not simply close the terminal window without shutting down the HAL session.

halcmd: exit3.7. Restoring the HAL configuration

To restore the HAL configuration stored in the file "saved.hal", we need to execute all of those HAL commands. To do that, we use "-f _<file name>_" which reads commands from a file, and "-I" (upper case i) which shows the halcmd prompt after executing the commands:

halrun -I -f saved.halNotice that there is not a "start" command in saved.hal. It’s necessary to issue it again (or edit the file saved.hal to add it there).

3.8. Removing HAL from memory

If an unexpected shutdown of a HAL session occurs you might have to unload HAL before another session can begin. To do this type the following command in a terminal window.

halrun -U4. Halmeter

You can build very complex HAL systems without ever using a graphical interface. However there is something satisfying about seeing the result of your work. The first and simplest GUI tool for the HAL is halmeter. It is a very simple program that is the HAL equivalent of the handy multimeter (or analog meter for the old timers).

It allows to observe the pins, signals or parameters by displaying the current value of these entities. It is very easy to use application for graphical environments. In a console type:

halmeterTwo windows will appear. The selection window is the largest and includes three tabs:

-

One lists all the pins currently defined in HAL,

-

one lists all the signals,

-

one lists all the parameters.

Click on a tab, then click on one of the items to select it. The small window will show the name and value of the selected item. The display is updated approximately 10 times per second. To free screen space, the selection window can be closed with the Close button. On the little window, hidden under the selection window at program launch, the Select button, re-opens the selection window and the Exit button stops the program and closes both windows.

It is possible to run several halmeters simultaneously, which makes it possible to visualize several items at the same time. To open a halmeter and release the console by running it in the background, run the following command:

halmeter &It is possible to launch halmeter and make it immediately display an item. For this, add pin|sig|par[am] name arguments on the command line. It will display the signal, pin, or parameter name as soon as it will start. If the indicated item does not exist, it will start normally.

Finally, if an item is specified for display, it is possible add -s in front of pin|sig|param to tell halmeter to use an even smaller window. The item name will be displayed in the title bar instead of below the value and there will be no button. This is useful for displaying a lot of halmeters in a small space.

We will use the siggen component again to check out halmeter. If you just finished the previous example, then you can load siggen using the saved file. If not, we can load it just like we did before:

halrun

halcmd: loadrt siggen

halcmd: loadrt threads name1=test-thread period1=1000000

halcmd: addf siggen.0.update test-thread

halcmd: start

halcmd: setp siggen.0.amplitude 5At this point we have the siggen component loaded and running. It’s time to start halmeter.

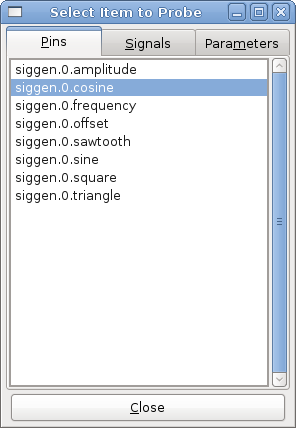

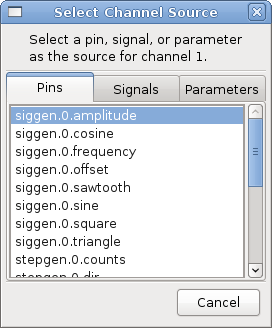

halcmd: loadusr halmeterThe first window you will see is the "Select Item to Probe" window.

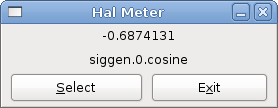

This dialog has three tabs. The first tab displays all of the HAL pins in the system. The second one displays all the signals, and the third displays all the parameters. We would like to look at the pin siggen.0.cosine first, so click on it then click the "Close" button. The probe selection dialog will close, and the meter looks something like the following figure.

To change what the meter displays press the "Select" button which brings back the "Select Item to Probe" window.

You should see the value changing as siggen generates its cosine wave. Halmeter refreshes its display about 5 times per second.

To shut down halmeter, just click the exit button.

If you want to look at more than one pin, signal, or parameter at a time, you can just start more halmeters. The halmeter window was intentionally made very small so you could have a lot of them on the screen at once.

5. Stepgen Example

Up till now we have only loaded one HAL component. But the whole idea behind the HAL is to allow you to load and connect a number of simple components to make up a complex system. The next example will use two components.

Before we can begin building this new example, we want to start with a clean slate. If you just finished one of the previous examples, we need to remove the all components and reload the RTAPI and HAL libraries.

halcmd: exit5.1. Installing the components

Now we are going to load the step pulse generator component. For a detailed description of this component refer to the stepgen section of the Integrator Manual. In this example we will use the velocity control type of StepGen. For now, we can skip the details, and just run the following commands.

In this example we will use the velocity control type from the stepgen component.

halrun

halcmd: loadrt stepgen step_type=0,0 ctrl_type=v,v

halcmd: loadrt siggen

halcmd: loadrt threads name1=fast fp1=0 period1=50000 name2=slow period2=1000000The first command loads two step generators, both configured to generate stepping type 0. The second command loads our old friend siggen, and the third one creates two threads, a fast one with a period of 50 microseconds (µs) and a slow one with a period of 1 millisecond (ms). The fast thread doesn’t support floating point functions.

As before, we can use halcmd show to take a look at the HAL. This time we have a lot more pins and parameters than before:

halcmd: show pin

Component Pins:

Owner Type Dir Value Name

4 float IN 1 siggen.0.amplitude

4 bit OUT FALSE siggen.0.clock

4 float OUT 0 siggen.0.cosine

4 float IN 1 siggen.0.frequency

4 float IN 0 siggen.0.offset

4 float OUT 0 siggen.0.sawtooth

4 float OUT 0 siggen.0.sine

4 float OUT 0 siggen.0.square

4 float OUT 0 siggen.0.triangle

3 s32 OUT 0 stepgen.0.counts

3 bit OUT FALSE stepgen.0.dir

3 bit IN FALSE stepgen.0.enable

3 float OUT 0 stepgen.0.position-fb

3 bit OUT FALSE stepgen.0.step

3 float IN 0 stepgen.0.velocity-cmd

3 s32 OUT 0 stepgen.1.counts

3 bit OUT FALSE stepgen.1.dir

3 bit IN FALSE stepgen.1.enable

3 float OUT 0 stepgen.1.position-fb

3 bit OUT FALSE stepgen.1.step

3 float IN 0 stepgen.1.velocity-cmd

halcmd: show param

Parameters:

Owner Type Dir Value Name

4 s32 RO 0 siggen.0.update.time

4 s32 RW 0 siggen.0.update.tmax

3 u32 RW 0x00000001 stepgen.0.dirhold

3 u32 RW 0x00000001 stepgen.0.dirsetup

3 float RO 0 stepgen.0.frequency

3 float RW 0 stepgen.0.maxaccel

3 float RW 0 stepgen.0.maxvel

3 float RW 1 stepgen.0.position-scale

3 s32 RO 0 stepgen.0.rawcounts

3 u32 RW 0x00000001 stepgen.0.steplen

3 u32 RW 0x00000001 stepgen.0.stepspace

3 u32 RW 0x00000001 stepgen.1.dirhold

3 u32 RW 0x00000001 stepgen.1.dirsetup

3 float RO 0 stepgen.1.frequency

3 float RW 0 stepgen.1.maxaccel

3 float RW 0 stepgen.1.maxvel

3 float RW 1 stepgen.1.position-scale

3 s32 RO 0 stepgen.1.rawcounts

3 u32 RW 0x00000001 stepgen.1.steplen

3 u32 RW 0x00000001 stepgen.1.stepspace

3 s32 RO 0 stepgen.capture-position.time

3 s32 RW 0 stepgen.capture-position.tmax

3 s32 RO 0 stepgen.make-pulses.time

3 s32 RW 0 stepgen.make-pulses.tmax

3 s32 RO 0 stepgen.update-freq.time

3 s32 RW 0 stepgen.update-freq.tmax5.2. Connecting pins with signals

What we have is two step pulse generators, and a signal generator. Now it is time to create some HAL signals to connect the two components. We are going to pretend that the two step pulse generators are driving the X and Y axis of a machine. We want to move the table in circles. To do this, we will send a cosine signal to the X axis, and a sine signal to the Y axis. The siggen module creates the sine and cosine, but we need wires to connect the modules together. In the HAL, wires are called signals. We need to create two of them. We can call them anything we want, for this example they will be X-vel and Y-vel. The signal X-vel is intended to run from the cosine output of the signal generator to the velocity input of the first step pulse generator. The first step is to connect the signal to the signal generator output. To connect a signal to a pin we use the net command.

halcmd: net X-vel <= siggen.0.cosineTo see the effect of the net command, we show the signals again.

halcmd: show sig

Signals:

Type Value Name (linked to)

float 0 X-vel <== siggen.0.cosineWhen a signal is connected to one or more pins, the show command lists the pins immediately following the signal name. The arrow shows the direction of data flow - in this case, data flows from pin siggen.0.cosine to signal X-vel. Now let’s connect the X-vel to the velocity input of a step pulse generator.

halcmd: net X-vel => stepgen.0.velocity-cmdWe can also connect up the Y axis signal Y-vel. It is intended to run from the sine output of the signal generator to the input of the second step pulse generator. The following command accomplishes in one line what two net commands accomplished for X-vel.

halcmd: net Y-vel siggen.0.sine => stepgen.1.velocity-cmdNow let’s take a final look at the signals and the pins connected to them.

halcmd: show sig

Signals:

Type Value Name (linked to)

float 0 X-vel <== siggen.0.cosine

==> stepgen.0.velocity-cmd

float 0 Y-vel <== siggen.0.sine

==> stepgen.1.velocity-cmdThe show sig command makes it clear exactly how data flows through the HAL. For example, the X-vel signal comes from pin siggen.0.cosine, and goes to pin stepgen.0.velocity-cmd.

5.3. Setting up realtime execution - threads and functions

Thinking about data flowing through "wires" makes pins and signals fairly easy to understand. Threads and functions are a little more difficult. Functions contain the computer instructions that actually get things done. Thread are the method used to make those instructions run when they are needed. First let’s look at the functions available to us.

halcmd: show funct

Exported Functions:

Owner CodeAddr Arg FP Users Name

00004 f9992000 fc731278 YES 0 siggen.0.update

00003 f998b20f fc7310b8 YES 0 stepgen.capture-position

00003 f998b000 fc7310b8 NO 0 stepgen.make-pulses

00003 f998b307 fc7310b8 YES 0 stepgen.update-freqIn general, you will have to refer to the documentation for each component to see what its functions do. In this case, the function siggen.0.update is used to update the outputs of the signal generator. Every time it is executed, it calculates the values of the sine, cosine, triangle, and square outputs. To make smooth signals, it needs to run at specific intervals.

The other three functions are related to the step pulse generators.

The first one, stepgen.capture_position, is used for position feedback. It captures the value of an internal counter that counts the step pulses as they are generated. Assuming no missed steps, this counter indicates the position of the motor.

The main function for the step pulse generator is stepgen.make_pulses. Every time make_pulses runs it decides if it is time to take a step, and if so sets the outputs accordingly. For smooth step pulses, it should run as frequently as possible. Because it needs to run so fast, make_pulses is highly optimized and performs only a few calculations. Unlike the others, it does not need floating point math.

The last function, stepgen.update-freq, is responsible for doing scaling and some other calculations that need to be performed only when the frequency command changes.

What this means for our example is that we want to run siggen.0.update at a moderate rate to calculate the sine and cosine values. Immediately after we run siggen.0.update, we want to run stepgen.update_freq to load the new values into the step pulse generator. Finally we need to run stepgen.make_pulses as fast as possible for smooth pulses. Because we don’t use position feedback, we don’t need to run stepgen.capture_position at all.

We run functions by adding them to threads. Each thread runs at a specific rate. Let’s see what threads we have available.

halcmd: show thread

Realtime Threads:

Period FP Name ( Time, Max-Time )

996980 YES slow ( 0, 0 )

49849 NO fast ( 0, 0 )The two threads were created when we loaded threads. The first one, slow, runs every millisecond, and is capable of running floating point functions. We will use it for siggen.0.update and stepgen.update_freq. The second thread is fast, which runs every 50 microseconds (µs), and does not support floating point. We will use it for stepgen.make_pulses. To connect the functions to the proper thread, we use the addf command. We specify the function first, followed by the thread.

halcmd: addf siggen.0.update slow

halcmd: addf stepgen.update-freq slow

halcmd: addf stepgen.make-pulses fastAfter we give these commands, we can run the show thread command again to see what happened.

halcmd: show thread

Realtime Threads:

Period FP Name ( Time, Max-Time )

996980 YES slow ( 0, 0 )

1 siggen.0.update

2 stepgen.update-freq

49849 NO fast ( 0, 0 )

1 stepgen.make-pulsesNow each thread is followed by the names of the functions, in the order in which the functions will run.

5.4. Setting parameters

We are almost ready to start our HAL system. However we still need to adjust a few parameters. By default, the siggen component generates signals that swing from +1 to -1. For our example that is fine, we want the table speed to vary from +1 to -1 inches per second. However the scaling of the step pulse generator isn’t quite right. By default, it generates an output frequency of 1 step per second with an input of 1.0. It is unlikely that one step per second will give us one inch per second of table movement. Let’s assume instead that we have a 5 turn per inch leadscrew, connected to a 200 step per rev stepper with 10x microstepping. So it takes 2000 steps for one revolution of the screw, and 5 revolutions to travel one inch. That means the overall scaling is 10000 steps per inch. We need to multiply the velocity input to the step pulse generator by 10000 to get the proper output. That is exactly what the parameter stepgen.n.velocity-scale is for. In this case, both the X and Y axis have the same scaling, so we set the scaling parameters for both to 10000.

halcmd: setp stepgen.0.position-scale 10000

halcmd: setp stepgen.1.position-scale 10000

halcmd: setp stepgen.0.enable 1

halcmd: setp stepgen.1.enable 1This velocity scaling means that when the pin stepgen.0.velocity-cmd is 1.0, the step generator will generate 10000 pulses per second (10 kHz). With the motor and leadscrew described above, that will result in the axis moving at exactly 1.0 inches per second. This illustrates a key HAL concept - things like scaling are done at the lowest possible level, in this case in the step pulse generator. The internal signal X-vel is the velocity of the table in inches per second, and other components such as siggen don’t know (or care) about the scaling at all. If we changed the leadscrew, or motor, we would change only the scaling parameter of the step pulse generator.

5.5. Run it!

We now have everything configured and are ready to start it up. Just like in the first example, we use the start command.

halcmd: startAlthough nothing appears to happen, inside the computer the step pulse generator is cranking out step pulses, varying from 10 kHz forward to 10 kHz reverse and back again every second. Later in this tutorial we’ll see how to bring those internal signals out to run motors in the real world, but first we want to look at them and see what is happening.

6. Halscope

Forrige eksempel lager noen svært interessante signaler. Men mye skjer for raskt til å se det med halmeter. For å ta en nærmere titt på hva som foregår på innsiden av HAL, så trenger vi et oscilloskop. Heldigvis har HAL et slikt som kalles halscope.

Halscope has two parts - a realtime part that reads the HAL signals, and a non-realtime part that provides the GUI and display. However, you don’t need to worry about this because the non-realtime part will automatically load the realtime part when needed.

With LinuxCNC running in a terminal you can start halscope with the following command.

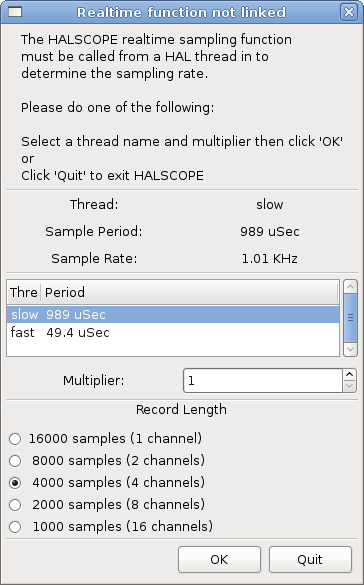

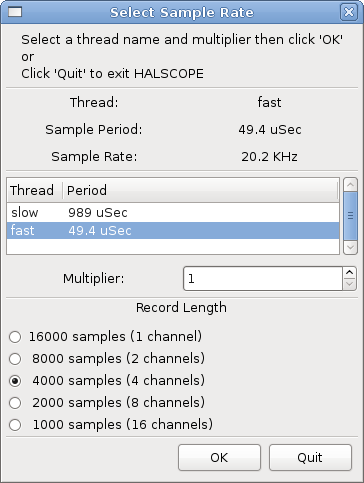

halcmd loadusr halscopeIf LinuxCNC is not running or the autosave.halscope file does not match the pins available in the current running LinuxCNC the scope GUI window will open, immediately followed by a Realtime function not linked dialog that looks like the following figure. To change the sample rate left click on the samples box.

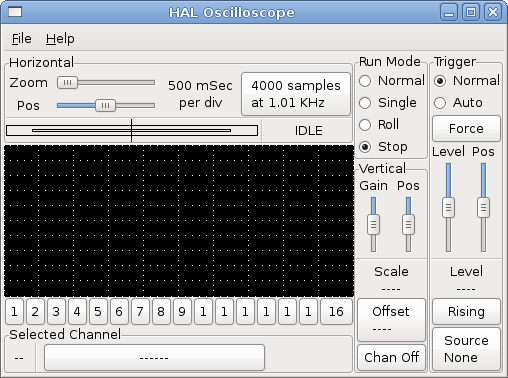

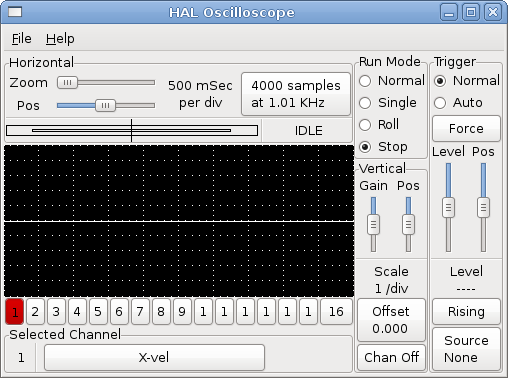

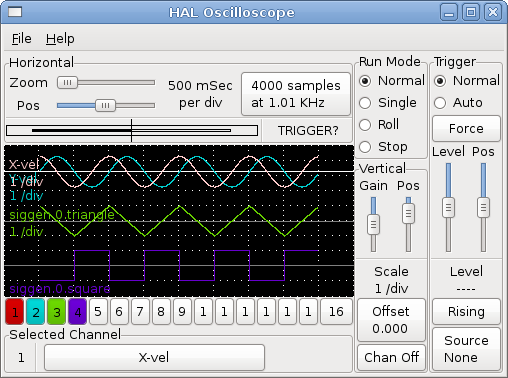

This dialog is where you set the sampling rate for the oscilloscope. For now we want to sample once per millisecond, so click on the 989 µs thread slow and leave the multiplier at 1. We will also leave the record length at 4000 samples, so that we can use up to four channels at one time. When you select a thread and then click OK, the dialog disappears, and the scope window looks something like the following figure.

6.1. Hooking up the scope probes

At this point, Halscope is ready to use. We have already selected a sample rate and record length, so the next step is to decide what to look at. This is equivalent to hooking virtual scope probes to the HAL. Halscope has 16 channels, but the number you can use at any one time depends on the record length - more channels means shorter records, since the memory available for the record is fixed at approximately 16,000 samples.

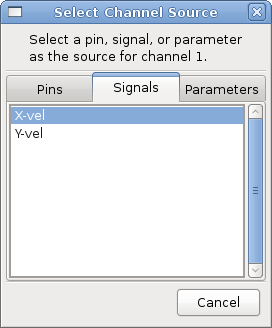

The channel buttons run across the bottom of the halscope screen. Click button 1, and you will see the Select Channel Source dialog as shown in the following figure. This dialog is very similar to the one used by Halmeter. We would like to look at the signals we defined earlier, so we click on the Signals tab, and the dialog displays all of the signals in the HAL (only two for this example).

To choose a signal, just click on it. In this case, we want channel 1 to display the signal X-vel. Click on the Signals tab then click on X-vel and the dialog closes and the channel is now selected.

The channel 1 button is pressed in, and channel number 1 and the name X-vel appear below the row of buttons. That display always indicates the selected channel - you can have many channels on the screen, but the selected one is highlighted, and the various controls like vertical position and scale always work on the selected one.

To add a signal to channel 2, click the 2 button. When the dialog pops up, click the Signals tab, then click on Y-vel. We also want to look at the square and triangle wave outputs. There are no signals connected to those pins, so we use the Pins tab instead. For channel 3, select siggen.0.triangle and for channel 4, select siggen.0.square.

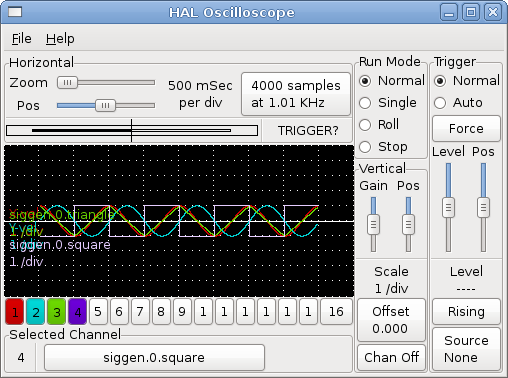

6.2. Capturing our first waveforms

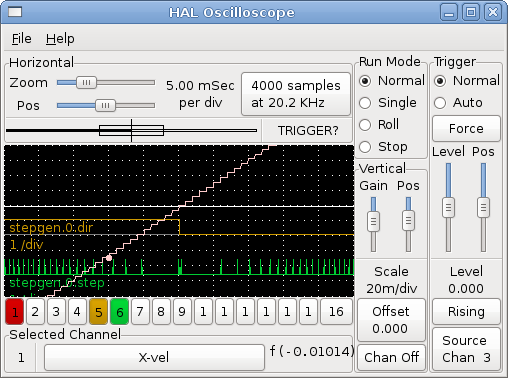

Now that we have several probes hooked to the HAL, it’s time to capture some waveforms. To start the scope, click the Normal button in the Run Mode section of the screen (upper right). Since we have a 4000 sample record length, and are acquiring 1000 samples per second, it will take halscope about 2 seconds to fill half of its buffer. During that time a progress bar just above the main screen will show the buffer filling. Once the buffer is half full, the scope waits for a trigger. Since we haven’t configured one yet, it will wait forever. To manually trigger it, click the Force button in the Trigger section at the top right. You should see the remainder of the buffer fill, then the screen will display the captured waveforms. The result will look something like the following figure.

The Selected Channel box at the bottom tells you that the purple trace is the currently selected one, channel 4, which is displaying the value of the pin siggen.0.square. Try clicking channel buttons 1 through 3 to highlight the other three traces.

6.3. Vertical Adjustments

The traces are rather hard to distinguish since all four are on top of each other. To fix this, we use the Vertical controls in the box to the right of the screen. These controls act on the currently selected channel. When adjusting the gain, notice that it covers a huge range - unlike a real scope, this one can display signals ranging from very tiny (pico-units) to very large (Tera-units). The position control moves the displayed trace up and down over the height of the screen only. For larger adjustments the offset button should be used.

The large Selected Channel button at the bottom indicates that channel 1 is currently selected channel and that it matches the X-vel signal. Try clicking on the other channels to put their traces in evidence and to be able to move them with the Pos cursor.

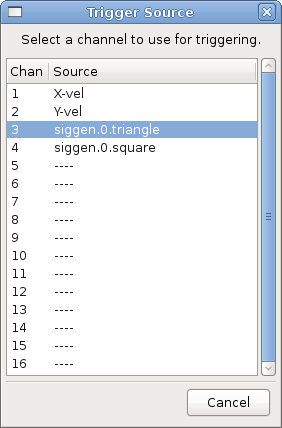

6.4. Triggering

Using the Force button is a rather unsatisfying way to trigger the scope. To set up real triggering, click on the Source button at the bottom right. It will pop up the Trigger Source dialog, which is simply a list of all the probes that are currently connected. Select a probe to use for triggering by clicking on it. For this example we will use channel 3, the triangle wave as shown in the following figure.

After setting the trigger source, you can adjust the trigger level and trigger position using the sliders in the Trigger box along the right edge. The level can be adjusted from the top to the bottom of the screen, and is displayed below the sliders. The position is the location of the trigger point within the overall record. With the slider all the way down, the trigger point is at the end of the record, and halscope displays what happened before the trigger point. When the slider is all the way up, the trigger point is at the beginning of the record, displaying what happened after it was triggered. The trigger point is visible as a vertical line in the progress box above the screen. The trigger polarity can be changed by clicking the button just below the trigger level display. It will then become descendant. Note that changing the trigger position stops the scope once the position has been adjusted, you relaunch the scope by clicking on the Normal button of Run mode the group.

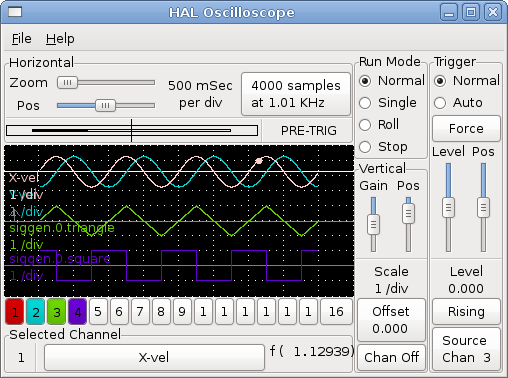

Now that we have adjusted the vertical controls and triggering, the scope display looks something like the following figure.

6.5. Horizontal Adjustments

To look closely at part of a waveform, you can use the zoom slider at the top of the screen to expand the waveforms horizontally, and the position slider to determine which part of the zoomed waveform is visible. However, sometimes simply expanding the waveforms isn’t enough and you need to increase the sampling rate. For example, we would like to look at the actual step pulses that are being generated in our example. Since the step pulses may be only 50 µs long, sampling at 1 kHz isn’t fast enough. To change the sample rate, click on the button that displays the number of samples and sample rate to bring up the Select Sample Rate dialog figure. For this example, we will click on the 50 µs thread, fast, which gives us a sample rate of about 20 kHz. Now instead of displaying about 4 seconds worth of data, one record is 4000 samples at 20 kHz, or about 0.20 seconds.

6.6. More Channels

Now let’s look at the step pulses. Halscope has 16 channels, but for this example we are using only 4 at a time. Before we select any more channels, we need to turn off a couple. Click on the channel 2 button, then click the Chan Off button at the bottom of the Vertical box. Then click on channel 3, turn if off, and do the same for channel 4. Even though the channels are turned off, they still remember what they are connected to, and in fact we will continue to use channel 3 as the trigger source. To add new channels, select channel 5, and choose pin stepgen.0.dir, then channel 6, and select stepgen.0.step. Then click run mode Normal to start the scope, and adjust the horizontal zoom to 5 ms per division. You should see the step pulses slow down as the velocity command (channel 1) approaches zero, then the direction pin changes state and the step pulses speed up again. You might want toincrease the gain on channel 1 to about 20 milli per division to better see the change in the velocity command. The result should look like the following figure.

6.7. More samples

If you want to record more samples at once, restart realtime and load halscope with a numeric argument which indicates the number of samples you want to capture.

halcmd loadusr halscope 80000If the scope_rt component was not already loaded, halscope will load it and request 80000 total samples, so that when sampling 4 channels at a time there will be 20000 samples per channel. (If scope_rt was already loaded, the numeric argument to halscope will have no effect).